通讯员 据烃加工新闻3月1日新闻消息称,英国石油公司和沙特基础工业公司签署了一项新协议,将在德国Gelsenkirchen化学工厂的石化活动中共同推动循环经济。凭借两家公司在生产基地的长期合作关系,新的合作将有助于增加使用混合塑料作为原料的认证循环产品的生产,从而减少现场石化工厂所需的化石资源。

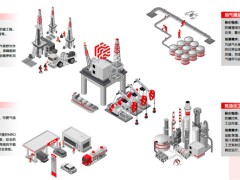

认证的循环聚合物是SABIC的TRUCIRCLE?产品组合的一部分,使用先进的回收技术将低质量的混合塑料和废旧塑料转化为热解油,原本将用于焚烧或填埋。这些油可作为传统化石材料的替代原料,将在BP的Gelsenkirchen炼油厂进行加工,然后由SABIC在Gelsenkirchen聚合物工厂中使用,以生产经认证的循环产品。最终的材料具有与原始聚合物相同的性能,并允许塑料反复回收,而不会损失任何特性或特性。经过2020年12月的成功试验后,今年年初,该工厂开始使用替代原料生产聚合物。

SABIC的PE和销售副总裁Fahad Al Swailem说:“SABIC致力于帮助创建一个永远不会浪费塑料的新型循环经济。先进的回收技术使我们能够生产更多可持续的材料,明智地利用地球上的资源,同时减少传统方法的使用,如填埋和燃烧。先进回收在当前的回收组合中扮演着至关重要的角色,因为它可以从传统上被忽视或丢弃的塑料废物流中获取价值。我们继续加强与上游供应商和下游客户的合作,与我们的长期合作伙伴BP的这项新举措使我们进一步实现了我们的愿景。”

BP和SABIC在Gelsenkirchen的石化产品上有着数十年的合作,这是鲁尔河北部地区化学工业网络价值链的起点。Gelsenkirchen的炼油和石化厂在德国人口最多的北莱茵-威斯特伐利亚州的化学工业中起着重要作用。英国石油公司在德国运营着最大的烯烃工厂之一,生产能力约为200万吨。

BP欧洲和非洲地区炼油和专业解决方案副总裁Wolfgang Stückle表示:“这是我们愿景中的一个重要里程碑,我们的目标是到2030年实现30%的乙烯和丙烯生产来自可持续、可回收的原材料。”

朱佳妮 摘译自 烃加工新闻

原文如下:

BP and Sabic sign circular economy agreement

BP and SABIC have signed a new agreement to work together to drive circular economy in the petrochemical activities at the Gelsenkirchen chemical complex in Germany. Building on a long-established relationship between the two companies at the production site, the new collaboration will help to increase production of certified circular products that take used mixed plastics to use as feedstock, thereby reducing the amount of fossil resources needed in the petrochemical plants at the site.

Certified circular polymers are part of SABIC’S TRUCIRCLE? portfolio and are produced using advanced recycling to convert low quality mixed and used plastic, otherwise destined for incineration or landfill, into pyrolysis oil. The oil, which acts as an alternative feedstock to traditional fossil materials, will be processed at BP’s Gelsenkirchen refining site and then used by SABIC in its Gelsenkirchen polymer plants to produce certified circular products. The final material has identical properties to virgin-based polymers and allows plastics to be recycled over and over again, with no loss of properties or characteristics. After successful trials in December 2020, polymer production using the alternative feedstock started at the site early this year.

“SABIC is committed to helping to create a new circular economy where plastic never becomes waste. Advanced recycling allows us to increase the production of more sustainable materials and use our planet’s resources wisely, whilst reducing the use of conventional approaches such as landfill and combustion. Advanced recycling has a crucial role to play in the current recycling mix as it can capture value from plastic waste streams that have traditionally been ignored or discarded,” said Fahad Al Swailem, Vice President, PE & Sales at SABIC. “We continue to increase our collaborations with upstream suppliers and downstream customers, and this new initiative with our long-term partner BP takes us one step further to achieving our vision.”

BP and SABIC have a collaboration going back decades in petrochemicals at the Gelsenkirchen site, which is the starting point for the value chain of the chemical industry’s network in the northern Ruhr Area. The refining and petrochemicals site in Gelsenkirchen plays an important role within the chemical industry in North Rhine-Westphalia, Germany’s most populous state. BP operates one of the largest olefin plants in Germany, with a production capacity of around 2 million t.

“This is an important milestone in our vision of achieving up to 30% of our ethylene and propylene production from sustainable, recyclable raw materials by 2030,” says Wolfgang Stückle, Vice President Refining and Specialities Solutions Europe & Africa at BP.