据烃加工4月27日消息,雷普索尔将加入Ecoplanta项目,与总部位于蒙特利尔的技术领先公司Enerkem和全球水和废物管理专家Agbar一起,在西班牙塔拉戈纳建设一座废料化工厂。

根据合资企业Ecoplanta分子回收解决方案,该工厂将处理来自周边地区的约40万吨不可回收的城市固体垃圾,并生产22万吨甲醇。

这种甲醇将被用作生产循环材料或先进生物燃料的原材料,有助于避免20万吨二氧化碳的排放,并减少最终进入垃圾填埋场的废物。这家多能源公司的目标是到2050年成为一家净零排放公司,而此次联盟则是朝着这个目标又迈进了一步。

该工厂是伊比利亚半岛的首个此类工厂,将由雷普索尔和Agbar共同管理,而Enerkem将是关键技术合作伙伴。在2022年第一季度做出项目最终投资决定后,该工厂预计将于2025年投入运营。该项目已经获得了地方政府《综合环境授权书》和《环境影响报告书》的批准。

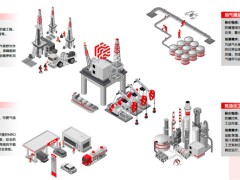

雷普索尔在塔拉戈纳有一个领先的工业综合体,这将有助于各设施之间的协同效应。这种石化工厂是西班牙同类企业中最重要的。在那里生产的许多类型的聚合物中,用于汽车领域的高度专业化的产品(例如高抗冲击性聚合物)非常突出。

雷普索尔化学品执行董事Jose Luis Bernal表示:“我们很高兴能与相关的废物管理和创新技术合作伙伴共同努力,展示我们对循环经济的承诺,并加强我们在2030年前回收20%聚烯烃生产的承诺。”

该工厂将利用气化技术将城市固体废物转化为甲醇等高附加值产品,由于其异质性这是一个非常复杂的过程。Enerkem公司拥有这项最先进的专利技术,在其位于埃德蒙顿(加拿大艾伯塔省)的商业示范工厂经过十多年从试点到示范到商业规模的严格规模升级后,该技术首次在工业规模上进行了测试,并在瓦雷纳斯(加拿大魁北克)正在建设的新设施。Enerkem首席执行官兼首席财务官Dominique Boies表示:“我们很荣幸地欢迎雷普索尔成为我们的合作伙伴,进一步支持我们在塔拉戈纳的工厂。他们在该行业的强大专业知识,加上Agbar的专业知识,将使我们能够利用我们独特的技术,将废物转化为可再生塑料或先进生物燃料,带来众多好处。”

有了这一重大投资,该项目已被选为进入欧盟创新基金的第二阶段,该阶段侧重于高度创新的技术和在欧洲实现显著减排的大型旗舰项目。

裘寅 编译自 烃加工

原文如下:

Repsol partners to build waste to chemicals plant in Tarragona

Repsol will join the Ecoplanta project, together with the technology leader Montreal-based firm Enerkem and Agbar, a global expert in water and waste management, to build a waste to chemicals plant in Tarragona, Spain.

Under the joint venture Ecoplanta Molecular Recycling Solutions, the plant will process around 400,000 tons of non-recyclable municipal solid waste from its surrounding regions and produce 220,000 tons of methanol.

This methanol will be used as raw material to produce circular materials or advanced biofuels, contributing to avoid 200,000 tons of CO2 and reducing the waste that ends up in the landfill. This alliance is a further step towards the multi-energy company's ambition to become a net-zero emissions company by 2050.

The plant, the first of its kind in the Iberian Peninsula, will be co-managed by Repsol and Agbar, whilst Enerkem will be the key technological partner. The plant is projected to be in operation in 2025 after taking the project’s final investment decision by the first quarter of 2022. The project already obtained the Integrated Environmental Authorization and the approval of the Environmental Impact Statement from the local authorities.

Repsol has a leading industrial complex in Tarragona, a factor that will allow for synergies among the facilities. This petrochemical complex is the most important of its kind in Spain. Among the many types of polymers produced there, the range of highly specialized products for the automotive sector, such as high impact resistant polymers, stands out.

According to Jose Luis Bernal, Repsol’s Executive Director for Chemicals: “We are very pleased to join forces with relevant waste management and innovative technology partners, showing our commitment to circular economy and reinforcing our commitment to recycle 20% of our polyolefins production by 2030”.

The plant will use gasification technology to transform municipal solid waste, a very complex process due to its heterogeneous nature, into high value-added products such as methanol. Enerkem is the owner of this patented state-of-the-art technology, the first to be tested on an industrial scale, after a rigorous scaleup from pilot to demonstration to commercial scale that took place over a decade, in its commercial demonstration plant in operation in Edmonton (Alberta, Canada), and a new facility under construction in Varennes (Québec, Canada). The Chief Executive Officer and Chief Financial Officer of Enerkem, Dominique Boies, mentioned: “We are proud to welcome Repsol as a partner to further support our Tarragona facility. Their strong expertise of the industry, coupled with that of Agbar, will enable us to feature the numerous benefits associated with our unique disruptive technology, transforming waste into renewable plastics or advanced biofuels.”

With this significant investment, the project has been selected to move into stage 2 of the European Union Innovation Fund, which focuses on highly innovative technologies and big flagship projects within Europe to bring on significant emission reductions.

免责声明:本网转载自其它媒体的文章,目的在于弘扬石化精神,传递更多石化信息,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以敬意。如果您认为本站文章侵犯了您的版权,请与我们联系,我们将第一时间删除。