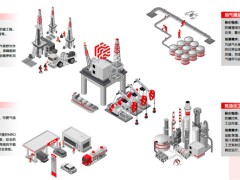

据油气新闻5月18日消息称,传统上,油气行业在互联技术的应用上一直比较落后,但如今,该行业越来越多地采用数字孪生技术来改善决策。GlobalData表示,由于COVID-19造成的行业普遍低迷,因此越来越需要降低成本,并借助技术使运营更具可持续性。

全球范围的封锁严重影响了全球能源需求,同时也因供应链中断导致项目延误。经济低迷加剧了改善整体资产可见度的需要,以确定降低成本的领域。数字孪生是实现这一目标并确保长期可持续运营的关键。

根据GlobalData的最新报告“石油和天然气中的数字孪生”, 这项技术的基础工作可能已经有一段时间了,但只有当盈利能力面临风险时,才会真正投入使用。顺便提一下,2014年油价崩盘后,油气行业一些重要的数字孪生项目才开始实施。2017年前后,BP开始大规模部署其APEX模拟和监测系统。

GlobalData的石油和天然气分析师Ravindra Puranik评论道:“公司已经开始建立模型,为‘如果发生什么’或‘将会发生什么’的问题提供答案。通过在虚拟世界中复制资产或资产的一部分,企业可以对现实世界中的问题进行模拟测试,并将结果以3D形式显示出来。这有助于项目工程师提高他们对资产的理解,从而使他们能够根据市场需求优化其性能。因此,数字孪生正逐渐成为油气业务不可或缺的一部分。”

与物联网(IoT)技术一样,缺乏标准化也在某种程度上阻碍了“数字孪生”的采用。为了克服这一限制,DNV GL与TechnipFMC合作,于2020年11月起草了一份创建和认证数字孪生的最佳实践指南。它为开发人员和用户提供了一个框架来理解数字双胞胎,并最大限度地利用它们的功能。

Ravindra补充说:“诸如Equinor的Johan Sverdrup或BP的Clair Ridge等较新的石油和天然气项目正在成为采用数字孪生的基准。壳牌、雪佛龙和巴西国家石油公司等公司正在启动在其全球投资组合中部署数字孪生的计划。在油田技术和服务公司的大力支持下,数字孪生很可能在未来几年成为油气业务的支柱。”

曹海斌 摘译自 油气新闻

原文如下:

Digital twins to become mainstay for oil and gas

The oil and gas industry, which is traditionally a laggard in the adoption of connected technologies, is increasingly deploying digital twins to improve decision-making. The prevailing industry downturn from COVID-19 has heightened the need to reduce costs and make operations more sustainable with technology, according to GlobalData.

Worldwide lockdowns have significantly impacted global energy demand, while also causing project delays due to supply chain disruptions. The downturn has aggravated the need for improving the overall asset visibility to identify areas for cost reduction. Digital twins are key to achieving this objective and ensuring sustainable operations in the long run.

According to GlobalData’s latest report, ‘Digital Twins in Oil & Gas’, the groundwork for this technology may have been in place for some time, but its actual deployment was seen only when profitability was at risk. Incidentally, some of the major digital twins in the oil and gas industry were implemented only after the oil price crash of 2014. BP began wide-scale deployment of its APEX simulation and surveillance system around 2017.

Ravindra Puranik, Oil & Gas Analyst at GlobalData, commented: “Companies have started to build models that will provide answers to ‘what if’ or ‘what will’ questions. By replicating an asset or a portion of it in the virtual world, companies can run simulation tests on real-world problems and visualise the results in 3D. This is helping project engineers to improve their understanding of the asset, thereby enabling them to optimise its performance as per the market requirements. Thus, digital twins are gradually becoming integral to oil and gas operations.”

Like Internet of Things (IoT) technologies, the lack of standardisation has somewhat hampered the adoption of digital twins as well. To overcome this limitation, DNV GL, in collaboration with TechnipFMC, drafted a best practices guide for the creation and certification of digital twins in November 2020. It provides a framework for developers and users alike to understand the digital twins and extract the most out of their capabilities.

Ravindra adds: “Newer oil and gas projects, such as Equinor’s Johan Sverdrup, or BP’s Clair Ridge, are emerging as benchmarks in digital twin adoption. Companies such as Shell, Chevron, and Petrobras are launching initiatives to deploy digital twins across their global portfolio. With crucial support from oilfield technology and service companies, digital twins are likely to become mainstay for oil and gas operations in the coming years.”

免责声明:本网转载自其它媒体的文章,目的在于弘扬石化精神,传递更多石化信息,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以敬意。如果您认为本站文章侵犯了您的版权,请与我们联系,我们将第一时间删除。