据世界石油5月31日伦敦报道,全球天然气行业正处于一场生死攸关的竞赛中:要么找到一种方式成为下一代能源的一部分,要么冒着被替代能源取代的风险。

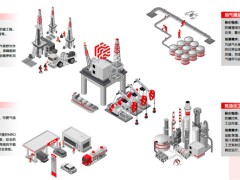

BP、挪威国家石油公司(Equinor)和荷兰皇家壳牌等石油生产商都在寻求氢气,以帮助确保需求,否则随着脱碳速度加快,需求可能会减弱。他们希望利用现有的管道、储油罐和燃料供应来制造蓝氢,这是一种使用天然气但捕获碳排放并将其储存的过程。

实现净零排放的最直接途径是使用可再生电力生产的氢——业内称之为“绿色氢”——但随着风能和太阳能的普及,预计至少到2030年,蓝色氢的价格将会更便宜。天然气公司现在的目标是降低排放,避免在未来十年被淘汰,它们正计划投入数十亿美元建设自己的蓝色业务。到2027年,英国、德国、挪威、荷兰、瑞典和新西兰将至少有15个项目上线。

总部位于挪威斯塔万格的Equinor负责开发和生产的执行副总裁阿尔·库克表示:“绿色是目的地,但我们将通过一条蓝色高速公路到达目的地。在某种程度上,绿色氢可能比蓝色氢的成本更低,但这可能至少在10年内不会发生。”

到2050年,清洁氢能满足世界四分之一的能源需求,年销售额达到6300亿欧元(7700亿美元)。据彭博新能源财经报道,蓝色氢的生产需要迅速扩大,因为到2030年无法上线的项目将面临失去竞争力的风险。

目前,在不排放温室气体的情况下,氢的制造成本很高,难以储存,而且极易燃烧,因此美国宇航局(NASA)用它来推动火箭进入太空。

尽管如此,国际能源署(IEA)在5月18日公布的净零排放路线图中表示,随着交通、钢铁和化工行业采取行动减少污染,到2050年的需求预计将增长6倍。

如今,几乎所有的氢气生产都使用天然气。这引起了试图减缓气候变化的 ESG 投资者、环保组织和政府的蔑视,因为最常见的方法,称为蒸汽-甲烷重整,也会产生大量的二氧化碳,排放到空气中。最快速的补救方法是捕获碳并将其储存在地下或重复利用。这种工艺已经存在了几十年,通常应用于天然气厂、肥料制造和乙醇生产设施。

目前,天然气比可再生电力便宜,即使增加了碳捕获和储存的成本,蓝氢仍具有优势。

壳牌负责氢能业务副总裁保罗·博格斯表示,加强碳捕获意味着蓝色氢能项目可以从第一天开始大规模推出。这家总部位于荷兰的公司参与了多个项目,包括英国的Acorn项目和Net Zero Teesside项目,这两个项目都计划于2025年上线。

将天然气换成氢气,是能源公司为满足越来越严格的减排要求而努力的一种方式。壳牌此前承诺在10年内将温室气体排放量减少20%,但海牙的一家法院在5月26日命令该公司在同一时期内将排放量削减45%。

天然气公司的紧迫性源于对绿色氢的普遍支持,这种氢由水和可再生电力制成。到2030年,绿色氢的成本预计将下降80%,在彭博新能源财经分析的所有28个市场中,绿色氢作为可再生能源和使用它来降低氢的电解槽的价格都比蓝氢更便宜。

欧洲最大的公用事业公司Iberdrola SA目前正专注于可再生能源和绿色氢能源,西班牙承诺将在能源转型上投入350亿欧元的欧盟刺激计划,这一举措得到了该公司的支持。美国工业巨头康明斯公司5月24日表示,它将与Iberdrola合作,在西班牙中部建立一家生产电解槽的工厂。

Iberdrola新风险投资主管Diego Diaz Pilas表示:"短期内,有机会投资蓝氢,但在中期(5--10年),这将是一项搁浅资产。"

裘寅 摘译自 世界石油

原文如下:

Natural gas producers jockey for position as focus shifts to hydrogen

The global natural gas industry is in an existential race: either find a way to be part of the next generation of energy or risk getting supplanted by alternatives.

BP, Sinopec, Equinor and Royal Dutch Shell are among the producers looking to hydrogen to help secure demand that otherwise may falter as decarbonization speeds up. They want to utilize existing pipelines, storage tankers and fuel supply to make blue hydrogen, a process that uses natural gas but captures the carbon emissions and stores them.

The straightest route to net-zero emissions uses hydrogen produced by renewable electricity -- known in the industry as green hydrogen -- but the blue variety is expected to be cheaper until at least 2030 as wind and solar power ramp up. Natural gas companies aiming to lower emissions now and avoid obsolescence next decade are planning to pour billions of dollars into building their blue businesses. At least 15 projects are scheduled to go online through 2027 in the UK, Germany, Norway, the Netherlands, Sweden and New Zealand.

“Green is the destination, but we’ll get there on a blue highway,” said Al Cook, executive vice president for development and production at Stavanger, Norway-based Equinor. “At some point, green hydrogen might well be lower cost than blue, but that will likely not be for at least a decade.”

Clean hydrogen could meet a quarter of the world’s energy needs by 2050, with annual sales reaching 630 billion euros ($770 billion). Production of blue needs to be scaled up quickly because projects that don’t come online by 2030 risk becoming uncompetitive, according to BloombergNEF.

Right now, hydrogen is expensive to make without expelling greenhouse gases, is difficult to store and is so highly combustible that NASA uses it to propel rockets into space.

Still, demand is expected to increase six-fold by 2050 as the transportation, steel and chemicals industries move to reduce pollution, the International Energy Agency said in its road map for net-zero emissions published May 18.

Natural gas is used in almost all hydrogen production today. That earns the disdain of ESG investors, environmental groups and governments trying to slow climate change because the most common method, called steam-methane reforming, also produces large amounts of carbon dioxide, which are dumped in the air. The quickest way to remedy that is by capturing the carbon and storing it underground or reusing it. The process has been around for decades, and it’s usually deployed in natural gas plants, fertilizer manufacturing and ethanol production facilities.

Gas currently is cheaper than renewable electricity, giving blue hydrogen an advantage even with the added costs of carbon capture and storage.

Bolting on carbon capture means blue hydrogen projects can be rolled out at scale from day one, said Paul Bogers, vice president for hydrogen at Shell. The Netherlands-based company is involved in several, including the UK’s Acorn Project and Net Zero Teesside, both scheduled to go online in 2025.

Swapping natural gas for hydrogen is one way energy companies could advance their efforts to meet increasingly strict mandates for lowering emissions. Shell previously pledged to reduce its greenhouse gas emissions by 20% within a decade, but a court in The Hague ordered the company on May 26 to slash them by 45% in the same time period.

The urgency for natural gas companies stems from the near-universal backing for green hydrogen, made from water and renewable electricity. The cost of green hydrogen is expected to fall 80% by 2030 and be cheaper than blue in all 28 markets analyzed by BNEF as renewable energy and the electrolyzers using it to make hydrogen both come down in price.

Iberdrola SA, Europe’s biggest utility, is focusing on renewable power and green hydrogen, bolstered by Spain’s commitment to spend 35 billion euros of EU stimulus on energy transition. American industrial giant Cummins Inc. said May 24 it will partner with Iberdrola to build a factory in central Spain for making electrolyzers.

“In the short term, there are opportunities in which you can apply blue, but in the midterm -- five to 10 years -- it’s going to be a stranded asset,” said Diego Diaz Pilas, head of new ventures at Iberdrola.

免责声明:本网转载自其它媒体的文章,目的在于弘扬石化精神,传递更多石化信息,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以敬意。如果您认为本站文章侵犯了您的版权,请与我们联系,我们将第一时间删除。