据全球能源新闻网6月12日报道,到2050年实现碳中和对于应对气候变化和降低地球温度至关重要。净零排放的未来依赖于大规模脱碳,而这只有通过部署碳中性燃料才有可能实现。

近几十年来,可再生能源,主要是风能,在向绿色世界转型的过程中发挥了关键作用,但只有在难以实现电气化的行业(如重型运输和重工业)向净零排放转型的情况下,无碳经济的愿景才能实现。风能产生的绿色氢气有可能成为这些行业期待已久的、对气候友好的解决方案,但要实现这一点,就必须尽快以成本效益和工业规模生产。

西门子Gamesa发布了一份行业白皮书《开启绿色氢革命》(Unlocking the Green Hydrogen Revolution),概述了一项雄心勃勃的计划,即到2030年从陆上风能和2035年从海上风能提供具有成本竞争力的绿色氢。Siemens Gamesa呼吁采取联合措施,鼓励市场需求和规模化生产,并强调了在未来10年内提供低成本绿色氢的4个关键要求:

•大幅提高可再生能源的容量,因为绿色氢革命依赖于此。到2050年,世界需要高达6000吉瓦的新可再生能源装机容量,高于目前的2800千兆瓦,以产生对氢气的预期需求(根据氢气理事会的数据,为5亿吨)。

•为绿色氢气创造一个具有成本效益的需求侧市场,以降低设备、基础设施和日常运营成本。目前,绿色制氢的主要运行成本是为电解槽供电,因此能源成本的降低了氢气的成本并增加了需求。

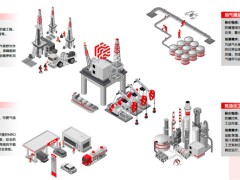

• 开发供应链,因为没有一家供应商可以拥有整个生产和分销流程。 目前,这些举措是分散的,因此成本高昂,这意味着可再生能源公司、电解槽制造商、网络供应商和水处理专家需要共同努力,建立一个有弹性的供应链。

•建立适当的物流、储存和配送基础设施。需要对氢气管道网络进行投资,以释放绿色氢气的潜力。

西门子Gamesa处于风电制氢解决方案的前沿,在能源转型中发挥着关键作用。其位于丹麦的Brande氢工厂已被丹麦能源局授予官方监管试验区的地位,为开发创新的绿色能源解决方案提供了更自由的框架。在这里,西门子Gamesa集成了一个电池、一个涡轮机和一个电解槽,作为几个技术途径的试验台,其中包括近期从现有风能项目生产绿色氢。此外,西门子Gamesa和西门子能源宣布,他们将联合开发一种创新的解决方案,将电解槽完全集成到海上风力涡轮机中,作为一个单独的同步系统,直接生产绿色氢气。该解决方案将能够脱离电网运行,开辟更多更好的风力发电站,从而降低氢气的成本。这两家公司的开发将成为一个实验平台,使大规模、低成本的氢气生产成为现实,并将证明可靠、有效地将风力涡轮机应用于可再生能源制氢系统的可行性。

郝芬 译自 全球能源新闻网

原文如下:

SIEMENS GAMESA – UNLOCKING THE GREEN HYDROGEN REVOLUTION

Achieving carbon neutrality by 2050 is crucial to fight climate change and reduce our earth’s temperature. A net-zero future relies on mass-decarbonization, which is only possible through the deployment of carbon-neutral fuels.

In recent decades, renewables, and mainly wind energy, have played a key role in the transition to a greener world, but the vision of a carbon-free economy can only be achieved if hard-to-electrify sectors, such as heavy transport and heavy industry, transition to net-zero emissions. Green hydrogen generated from wind energy has the potential to be the long-awaited, climate-friendly solution for these industries but, for this to become a reality, it needs to be produced cost-effectively and at industrial scale soon.

Siemens Gamesa launched an industry whitepaper, Unlocking the Green Hydrogen Revolution, that outlines an ambitious plan to deliver cost-competitive green hydrogen by 2030 from onshore wind and by 2035 from offshore wind. Siemens Gamesa calls for a joined-up approach to encouraging both market demand and scaling production, highlighting four key requirements to deliver low-cost green hydrogen within the next decade:

• Increase drastically the capacity of renewables because the green hydrogen revolution relies on this. The world needs up to 6,000 GW of new installed renewable energy capacity by 2050, up from 2,800 GW today to generate the expected demand for hydrogen (500 million tonnes, according to the Hydrogen Council).

• Create a cost-effective demand-side market for green hydrogen to drive down the costs of equipment, infrastructure and day-to-day operating costs. Currently, the main operating cost for green hydrogen production is powering the electrolyzers, so a decrease in energy costs lowers the cost of the hydrogen and increases demand.

• Develop the supply chain as no one provider can own the entire production and distribution process. At the moment, initiatives are fragmented, and therefore costly, meaning renewable energy companies, electrolyzer manufacturers, network providers and water treatment specialists need to work together to build a resilient supply chain.

• Build the right infrastructure in terms of logistics, storage and distribution. There needs to be investment in hydrogen pipeline networks to unlock the potential of green hydrogen

Siemens Gamesa is at the forefront of wind-to-hydrogen solutions, playing a pivotal role in the energy transition. Its Brande Hydrogen site in Denmark has been granted status as official regulatory test zone by the Danish Energy Agency, providing a freer framework to develop innovative green energy solutions. Here, Siemens Gamesa has integrated a battery, a turbine and an electrolyzer to serve as a test bed for several technology pathways, here among the production of green hydrogen in the near term from existing wind projects. In addition, Siemens Gamesa and Siemens Energy announced that they were joining forces contributing their developments to an innovative solution that fully integrates an electrolyzer into an offshore wind turbine as a single synchronized system to directly produce green hydrogen. The solution will lower the cost of hydrogen by being able to run off grid, opening up more and better wind sites. The companies’ developments will serve as a test bed for making large-scale, cost-efficient hydrogen production a reality and will prove the feasibility of reliable, effective implementation of wind turbines in systems for producing hydrogen from renewable energy.

免责声明:本网转载自其它媒体的文章,目的在于弘扬石化精神,传递更多石化信息,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以敬意。如果您认为本站文章侵犯了您的版权,请与我们联系,我们将第一时间删除。