据管道&天然气杂志网7月15日报道,全球大约有28个商业碳捕获利用和存储设施(CCUS),每年总容量为4000万吨,但只占能源相关二氧化碳排放总量的0.12%。关于国际能源机构(IEA)2050年的净零排放情况,CCUS在脱碳经济中发挥了重要作用,根据数据和分析公司GlobalData称,生产能力需要提高190倍,每年达到76亿吨。

2021年5月25日,美国国会通过了两党合作的CATCH法案,将每公吨二氧化碳的碳捕获信用额从50美元提高到85美元。这一政策将成为整个价值链中许多油气利益相关者的巨大驱动力,因为目前发电中捕获碳的成本为每吨二氧化碳40-80美元。

能源部门约占温室气体排放(GHG)总量的四分之三。根据IEA的数据显示,2018年二氧化碳排放量达到335亿吨/年的高点,2019年和2020年分别降至334亿吨/年和315亿吨/年,主要由于新冠肺炎经济危机。与总排放水平相比,CCUS的容量相对较小,需要全球政府和行业领导的共同努力来加大CCUS设施的部署。

Global Data上游油气分析师Steven Ho表示,目前CCUS项目的发展主要是出于商业和商业考虑。在28个作业设施中,有22个是由于利用CO2进行强化采油作业所产生的额外经济价值而受到激励的。然而,在2020年期间,计划新建的碳捕获和储存设施显著增加。到2028年,这些新增产能将达到7200万吨。

他表示,许多已经在建的设施都是在发电领域。去年,他们占新增产能的67%。就燃煤或化石燃料发电厂而言,改造现有发电厂是近期最具成本效益的选择,特别是在仍严重依赖化石燃料和煤炭的亚洲新兴经济体。预计到2025年,化学生产和氢气生产行业的额外CCS能力也将商业化开发,分别增加约1400万吨/年和540万吨/年的碳捕获能力。

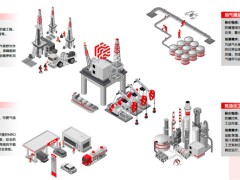

随着越来越多的企业开始对 CCUS 表现出兴趣和投资,CCUS 产业枢纽和集群的形成变得更加普遍。这可以通过扩大规模经济和降低投资风险使所有有关各方受益。这些枢纽中心的工作是将二氧化碳流聚集、压缩、脱水,并将其从集散地输送到存储地。未来氢需求的增加也是增加CCS产能的激励因素。将CCS添加到主要的蒸汽甲烷重整过程中,其经济成本比使用可再生电力通过电解生产氢气等要低。

Ho继续道,2030年后,进一步部署碳捕获设施很有可能弥补水泥等难以减少的行业的剩余碳排放,并要求到2050年捕获高达76亿吨/年的二氧化碳,以实现净零排放。

郝芬 译自 管道&天然气杂志网

原文如下:

Globaldata: Significantly More Carbon Capture Infrastructure Needed to Achieve Net-Zero Emissions

There are approximately 28 commercial Carbon Capture Utilization and Storage facilities (CCUS) globally, with a total capacity of 40 Megatons per annum (Mtpa), but accounting for only 0.12% of total energy-related CO2 emissions. In reference to the net-zero emissions by 2050 scenario by International Energy Agency (IEA), CCUS plays a significant role in a decarbonized economy and capacity needs to be ramped-up by 190-fold, and to as much 7.6 Gigatons per annum (Gtpa), according to GlobalData, a data and analytics company.

On May 25, 2021, U.S. Congress passed the bipartisan CATCH Act to increase the carbon capture credit from $50 to as high as $85 per metric ton of CO2. This policy will be a huge driver for many oil and gas stakeholders across the value chain, as the current cost to capture carbon in power generation ranges from $40 to $80 per ton of CO2.

The energy sector accounts for approximately three quarters of total greenhouse gas (GHG) emissions. According to IEA, CO2 emissions reached a high of 33.5 Gtpa in 2018 and have reduced to 33.4 Gt in 2019 and 31.5 in 2020, mainly due to the Covid-19 economic crisis. In comparison to the total emissions level, CCUS capacity is relatively insignificant and requires a collective effort from global government and industry leaders to ramp up the deployment of CCUS facilities.

“The current development of CCUS projects is mainly driven by business and commercial considerations. Out of the 28 operational facilities, 22 are incentivized by the additional economic value created from using CO2 for Enhanced Oil Recovery (EOR) operations,” said Steven Ho, upstream oil & gas analyst at GlobalData. “However, during 2020 there has been a noticeable increase in the planned new carbon capture and storage facilities. These would add up to 72 Mtpa of additional capacity by 2028.”

Many of the facilities already in construction are in the power generation sector, he said. In 2020, they account for 67% of additional capacity.

“For coal or fossil fuel power plants, retrofitting existing plants is the most cost-effective option in the near term, especially in growing economies in Asia that are still heavily dependent on fossil fuel and coal,” Ho said. “Additional CCS capacity in chemical production and hydrogen production industries are also expected to be commercially developed by 2025, adding up to approximately 14 Mtpa and 5.4 Mtpa of carbon capture capacity, respectively.”

As more parties are beginning to show interest and investing in CCUS, the formation of CCUS industrial hubs and clusters become more common. These can benefit all involved parties by increasing economies of scale and reduce investment risk. These hubs work to aggregate, compress, dehydrate and transport CO2 streams from clusters of facilities to storage sites. An increase in future hydrogen demand is also an incentive for additional CCS capacity. Adding CCS to the dominant steam methane reformation process, has a lower economic cost than, for instance, producing hydrogen through electrolysis using renewable electricity.

Ho continues: “Beyond 2030, further deployment of carbon capture facilities becomes a very likely scenario to compensate for the remaining carbon emissions that remain from a hard-to-abate industry, such as cement, and require to capture up to 7.6 Gtpa by 2050 to achieve net-zero carbon emissions.”

免责声明:本网转载自其它媒体的文章,目的在于弘扬石化精神,传递更多石化信息,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以敬意。如果您认为本站文章侵犯了您的版权,请与我们联系,我们将第一时间删除。