据烃加工2022年3月16日报道,霍尼韦尔日前宣布了一套集成烯烃套件(IOS)新技术,该新技术可以增加石脑油蒸汽裂解装置的乙烯产量,并提高盈利能力。 IOS将为客户提供提高投资回报、增加运营利润、减少二氧化碳排放量和提高副产品控制水平的机会。

IOS的特点是一组经过商业验证的技术,在石脑油蒸汽裂解性能上产生步长变化。 通过经济地提高石脑油裂解原料的质量,提高乙烯产量,降低低价值副产品的产量。

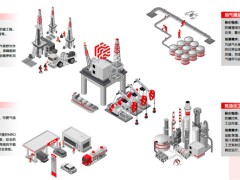

IOS包括三个主要部分。 原料优化部分将典型的石脑油转化为富含正链烷烃的石脑油裂解原料。 正链烷烃将增加乙烯的产量,但降低大部分副产品的产量,有望产生更有价值的产品。

在UOP Oleflex装置中,协同处理部分通过处理丙烷显著增加丙烯,丙烷是在原料优化部分和其他原料来源生成的。 与在蒸汽裂解装置中处理丙烷相比,Oleflex工艺将提供高得多的轻烯烃产量,同时也产生大量有价值的氢气。

副产品处理部分包括额外的处理解决方案,可以用来增加、减少或消除副产品的生产,如丁二烯、丁烯和苯,以匹配客户的战略目标。

霍尼韦尔UOP过程技术业务高级业务发展总监Alan Cepla表示:“IOS是行业内的首个此类产品,它创造差异化的产品,以提高石脑油裂解装置的性能,并提高其竞争力。”“ 霍尼韦尔UOP的IOS系统可以生产更有价值的产品,增加轻烯烃的产量,并定制副产品,以满足客户的战略目标。”

李峻 编译自 烃加工

原文如下:

Honeywell announces technology to improve naphtha steam cracker performance

Honeywell announced an integrated olefin suite (IOS) of technologies that can increase ethylene production and improve profitability when added to a naphtha steam cracker. IOS provides customers the ability to improve return on investment, increase operating profits, opportunity to reduce CO2 footprint and increase the level of control over by-products.

IOS features a collection of commercially proven technologies that create a step change in naphtha cracker performance. By economically improving the quality of naphtha cracker feeds, the yield of ethylene is increased and the production of lower-value by-products are reduced.

IOS includes three main sections. The feed optimization section transforms typical naphthas into a naphtha cracker feedstock that is rich in normal paraffins. Normal paraffins increase the yield of ethylene and decrease the yield of most by-products which is expected to generate a more valuable product slate.

The co-processing section significantly increases propylene by processing propane, generated in the feed optimization section and from other feed sources, in a UOP Oleflex unit. When compared to processing propane in a steam cracking unit, the Oleflex process provides a much higher yield to light olefins, while also generating significant amounts valuable hydrogen.

The by-products handling section includes additional processing solutions that can be used to increase, decrease or eliminate the production of by-products such as butadiene, butenes and benzene to match the customer’s strategic objectives.

“The IOS is the first of its kind in the industry and creates differentiated offerings to enhance the performance of naphtha crackers and improve their competitiveness,” said Alan Cepla, Senior Business Development Director, UOP Process Technologies Business. “Honeywell UOP’s IOS produces a more valuable product slate, increasing light olefin production and tailoring by-products to meet your strategic objectives.”

免责声明:本网转载自其它媒体的文章及图片,目的在于弘扬石化精神,传递更多石化信息,宣传国家石化产业政策,展示国家石化产业形象,参与国际石化产业舆论竞争,提高国际石化产业话语权,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以崇高敬意。如果您认为本站文章及图片侵犯了您的版权,请与我们联系,我们将第一时间删除。