据气体世界网2022年7月6日报道,英国知名研究公司IDTechEx最近披露的一项研究报告显示,由于越来越多的行业开始利用碳捕获技术,通过将捕获的二氧化碳转化为低碳、可降解的聚合物,这种技术可以帮助减少碳排放和塑料垃圾。

IDTechEx的这份题为《2022-2042:二氧化碳利用技术、市场预测和参与者》的报告探讨了与二氧化碳聚合物技术相关的机遇和挑战。

2019年,全球塑料产量达到4.6亿吨,尽管近几年来使用了更多基于回收的技术,但经合组织的一项研究显示,全球塑料消费仍将会增加。

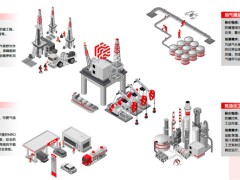

为了促进循环碳经济,捕获的碳可以利用电化学、生物转化和热催化来制造各种聚合物。

热催化被认为是最成熟的二氧化碳利用技术,它可以直接产生生物可降解的线性链聚碳酸酯(LPCs),或者通过使用甲醇和乙醇等化学物质进行聚合反应来间接利用。

诸如聚氨酯(PUR)那样的LPCs通常用于电子、地膜、泡沫和生物医药/保健等行业。聚氨酯的主要成分之一是多元醇,它可以组成高达50%(在重量上)的二氧化碳。

为了制造这些多元醇,二氧化碳先与环醚(一种环状分子,称为环氧化合物,含氧)结合,然后再与异氰酸酯组成合成PUR。

虽然不是完全无碳的,但在通过热化学法制造塑料时,以化石为基础的过程是由废弃的二氧化碳来支持的,以节省原材料成本。

电化学和微生物合成等不太成熟的技术还在开发中。

微生物合成等生物过程被认为比电化学过程更成熟,已经达到早期的商业化阶段,美国加州的Newlight公司已经开发出一种利用特定微生物将捕获的二氧化碳、空气和甲烷转化为可降解聚合物的方法。

根据这份报告,目前其他成功的商业操作包括日本旭化成公司从二氧化碳中生产芳香族聚碳酸酯的努力。总部位于美国的朗泽技术公司还与联合利华(Unilever)、欧莱雅(L’oreal)、安恩(On)和达能(Danone)等主要品牌合作,从工业过程中捕获的碳排放中生产聚合物前驱体。

尽管这是一项明显的“双赢”技术,但人们仍然担心它是否真的会导致大量碳排放,以及潜在的经济障碍,可能会减缓商业化。

IDTechEx表示:“由于世界对塑料的渴求似乎没有减弱,循环碳经济通过培育一个将废弃的二氧化碳视为可行原料的石化行业可能有助于维持人们的生活方式。”

李峻 编译自 气体世界网

原文如下:

Turning CO2 into plastics

As more industries begin to utilise carbon capture, technologies could help reduce both emissions and plastic waste by turning captured CO2 into low-carbon, degradable polymers, according to a recent study by IDTechEx.

The report, titled ‘Carbon Dioxide (CO2) Utilisation 2022-2042: Technologies, Market Forecasts, and Players’ explored both opportunities and challenges associated with CO2-based polymer technology.

In 2019, global plastic production rates hit 460m tonnes and - although more recycling-based technologies have been deployed in recent years - an OECD study revealed that plastic consumption is set to increase.

To advance a circular carbon economy, captured carbon could be utilised to created various polymers with electrochemistry, biological conversion, and thermocatalysis.

Considered more developed than electrochemical processes, biological processes such as microbial synthesis have reached the early-commercialisation stage, with companies such as California-based Newlight having developed a method to turn captured CO2, air, and methane into degradable polymer using a specific microbe.

According to the report, other successful commercial operations currently include Asah Kasei’s efforts to make aromatic polycarbonates from CO2.

US-based LanzaTech has also worked with major brands such as Unilever, L’Oreal, On, and Danone to make polymer precursors from carbon emissions captured from industrial processes.

Despite it being an apparent ‘win-win’ technology, there are still concerns over whether it will actually lead to significant emissions, in addition to potential financial barriers that may slow down commercialisation.

“As the world’s thirst for plastics does not seem to fade, a circular carbon economy may help maintain people’s lifestyles by fostering a petrochemical industry that sees waste CO2 as a viable feedstock,” stated IDTechEx.

Considered more developed than electrochemical processes, biological processes such as microbial synthesis have reached the early-commercialisation stage, with companies such as California-based Newlight having developed a method to turn captured CO2, air, and methane into degradable polymer using a specific microbe.

According to the report, other successful commercial operations currently include Asah Kasei’s efforts to make aromatic polycarbonates from CO2.

US-based LanzaTech has also worked with major brands such as Unilever, L’Oreal, On, and Danone to make polymer precursors from carbon emissions captured from industrial processes.

Despite it being an apparent ‘win-win’ technology, there are still concerns over whether it will actually lead to significant emissions, in addition to potential financial barriers that may slow down commercialisation.

“As the world’s thirst for plastics does not seem to fade, a circular carbon economy may help maintain people’s lifestyles by fostering a petrochemical industry that sees waste CO2 as a viable feedstock,” stated IDTechEx.

免责声明:本网转载自其它媒体的文章及图片,目的在于弘扬石化精神,传递更多石化信息,宣传国家石化产业政策,展示国家石化产业形象,参与国际石化产业舆论竞争,提高国际石化产业话语权,并不代表本网赞同其观点和对其真实性负责,在此我们谨向原作者和原媒体致以崇高敬意。如果您认为本站文章及图片侵犯了您的版权,请与我们联系,我们将第一时间删除。